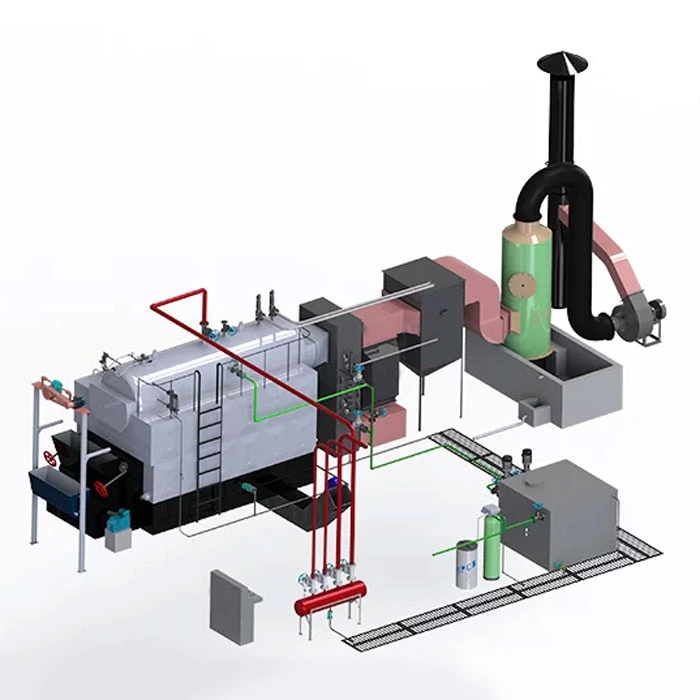

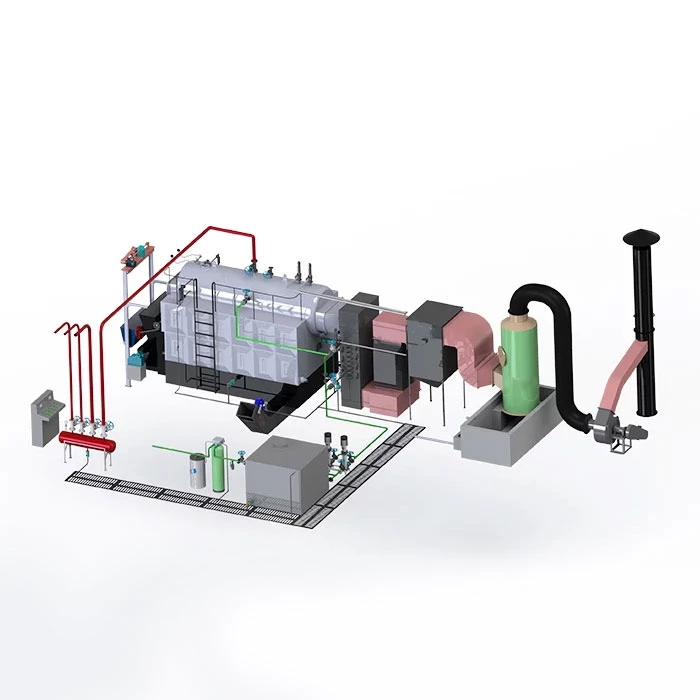

Special coal-fired biomass fired steam boilers for chemical industry

Boiler Type: Single Drum Coal Biomass Fired Steam Boiler

Capacity: 1~20 T/h

Pressure: 0.7~ 1.6 M Pa

Fuel: Any Type of Coal you want to use.

Application: Chemical factory.

Technical Parameters

Choose the right parameters and let us design a more suitable coal-fired steam boiler solution for you. If you have no good ideas, you can contact us. Let us find a way together.

| Item/Type | Special coal-fired biomass fired steam boiler for chemical industry | |||||||||

| Rated capacity t/h | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 15 | 20 | |

| Rated steam pressure MPa | 0.7/1.25 | 0.7/1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | |

| Rated steam temperature ℃ | 170/194 | 170/194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | |

| Feed water temperature ℃ | 20 | |||||||||

| Boiler thermal efficiency % | 78.1 | 80.2 | 82.3 | 82.5 | 82.5 | 82.9 | 82.9 | 83.1 | 83.1 | |

| Body heating area m2 | 22.99 | 48.7 | 96.34 | 148.15 | 174.4 | 226.2 | 276 | 374.5 | 669 | |

| Fuel & consumption | Fuel type | Class II Soft Coal, Biomass, Wood Chips, Wood Pellets, Rice Husk, Palm Kernel Shell, etc. |

||||||||

| Coal kg/h | 118.76 | 231.30 | 450.79 | 674.54 | 899.39 | 1118.81 | 1342.57 | 1674.18 | 2232.23 | |

| Biomass kg/h | 171.63 | 334.27 | 651.48 | 974.85 | 1299.81 | 1616.92 | 1940.30 | 2419.54 | 3226.05 | |

| Size of boiler largest parts mm |

Length | 4600 | 5800 | 6700 | 7000 | 7300 | 7600 | 7600 | 8500 | 9500 |

| Width | 1900 | 2600 | 2700 | 3000 | 3000 | 3200 | 3200 | 3400 | 3800 | |

| Height | 2900 | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | 7100 | |

| Weight of boiler largest parts ton |

18 | 22 | 30.1 | 40 | 21/14 | 23/17 | 23/19 | 21/24 | 25/24 | |

Product Advantage

First, assess the coal price and select the coal type, then design the boiler structure based on the chosen coal. The design must meet three key criteria: 1. Ensure complete combustion with no fuel wastage 2. Maintain micro-negative pressure combustion to supply just enough air for full fuel combustion, minimizing excess exhaust gas 3. Minimize heat loss through a high-quality insulation layer that effectively retains boiler heat.

The coal-fired steam boiler incorporates a high-efficiency heat transfer component featuring threaded flue gas tubes, with an optimized heating surface and flue gas velocity, achieving thermal efficiency that surpasses the national standard by 6 to 8 percentage points. Moreover, the furnace and air duct system are strategically designed to enhance complete fuel combustion.

The boiler is designed for simplicity and ease of operation. We supply an electronic control system tailored to the experience of boiler operators in your local market, incorporating automation programs and programmed functions to handle specialized and complex tasks efficiently.

Auxiliary boiler accessories will be selected based on your specific requirements, ensuring the dust removal performance meets your standards. The boiler system is tailored to align closely with your factory’s operational needs, delivering cost savings across multiple areas. With experience designing boiler systems for over 15,000 companies, EPCB has consistently helped clients reduce unnecessary expenses and has earned widespread recognition for its expertise.

The drum of the coal-fired steam boiler features a large capacity, allowing for greater water storage and more efficient separation of steam and water, resulting in higher steam dryness. Equipped with a threaded flue gas pipe, it facilitates enhanced heat exchange between high-temperature flue gas and water. Compared to conventional boilers, this design improves steam quality by over 50% and increases thermal efficiency by more than 20%.